Introduction:

Robotics and artificial intelligence breakthroughs in recent years have changed a variety of industries, including manufacturing, logistics, healthcare, and others. Robot Enfejar is a notable technology in this field which is designed to improve automation and streamline processes, has numerous advantages for firms looking to increase efficiency and productivity. In this post, we will look at the best ways to use Robot Enfejar and maximize its potential for operations optimization.

Understand Your demands:

Before incorporating Robot Enfejar into your workflow, you must first understand your organization’s specific demands and pain concerns. Analyze your operations thoroughly, identifying areas where automation could be most advantageous. Knowing what you want to achieve, whether it’s repetitive jobs, material handling, quality control, or data entry, can help you establish how Robot Enfejar can best serve your needs.

Selecting the Right Robot Enfejar Model:

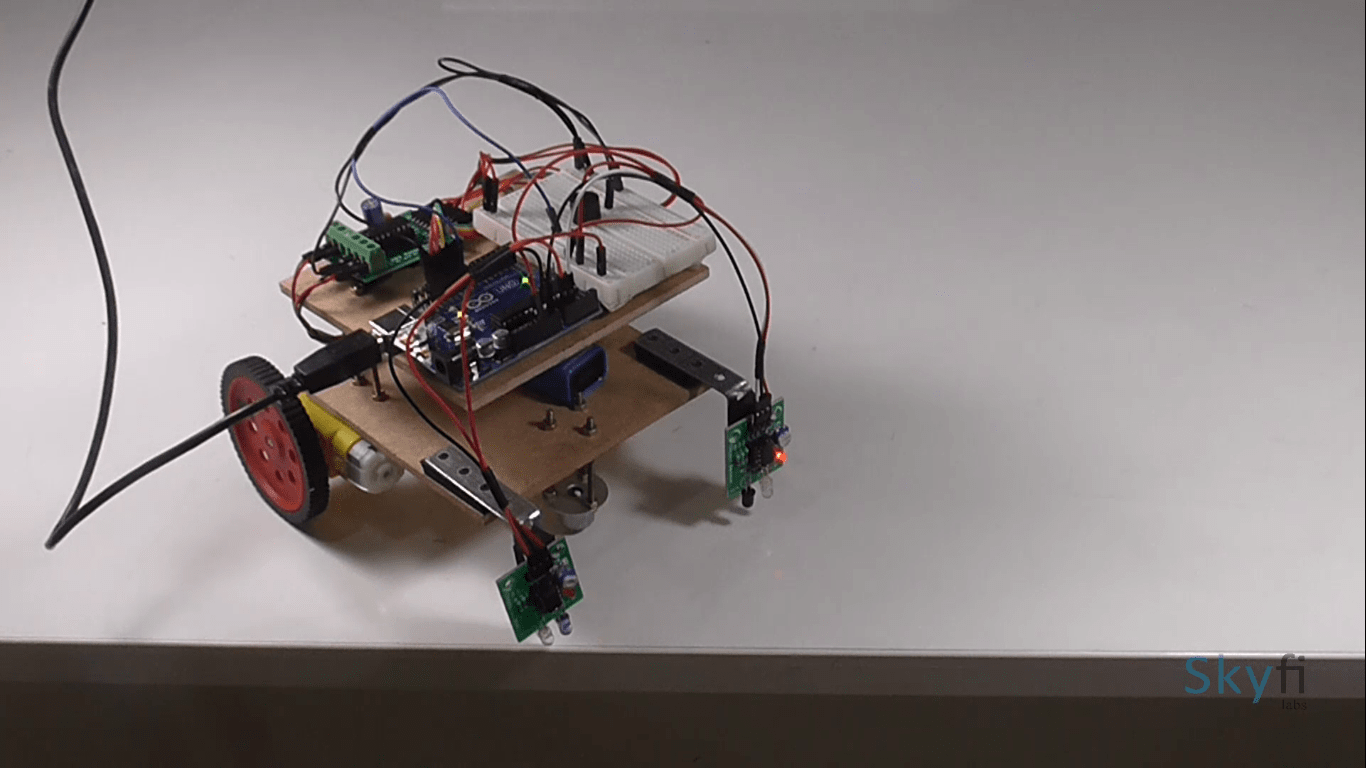

Robot Enfejar is available in a variety of models, each adapted to specific jobs and settings. When choosing the best robot for your needs, consider elements such as payload capacity, reach, precision, and mobility. Collaborative robots (cobots) may be best suited for scenarios requiring human-robot collaboration, whereas industrial robots may be better suited for heavy-duty production activities.

Optimize Workflows for Robot Integration:

For a smooth implementation, it is critical to prepare your processes for Robot Enfejar integration. Work with your technical team and the provider to rearrange workflows so that human workers and the robot can interact smoothly. Identify possible bottlenecks and create a plan that improves robot productivity while minimizing disruption to existing processes.

Ensure Safety and Training:

When working with robots in any environment, safety is of the utmost importance. Conduct extensive risk assessments and put safety standards in place to protect both human workers and the robot. Train personnel on how to work safely and successfully alongside on a regular basis. Encourage a collaborative and open communication culture to resolve any concerns about the robot’s integration.

Connect Robot Enfejar to Existing Systems:

Robot Enfejar is most effective when it is smoothly linked with your existing software and processes. Connecting to your manufacturing execution system (MES), enterprise resource planning (ERP) software, or quality control systems helps improve data sharing and overall process optimization.

Monitor and Analyze Performance:

Track Robot Enfejar’s performance on a regular basis and analyze data to identify areas for improvement. To assess the robot’s influence on productivity, consider indicators such as cycle times, mistake rates, and downtime. Make data-driven decisions and fine-tune your processes to achieve the best results.

Conclusion:

Robot Enfejar is a game-changing technology that has the potential to redefine the way businesses function by increasing efficiency and productivity. You can unlock the full potential of Robot Enfejar by understanding your goals, selecting the proper model, optimizing workflows, emphasizing safety, connecting with existing systems, and analyzing performance. Adopt a culture of continual learning and adaptation to keep your company at the forefront of the automation revolution. Those who embrace the ability of robots like to optimize and elevate their operations will have a bright future.